Again, There is no intention here to imply that any of the procedures discussed here are safe, legal or even sane. I take no responsibility for what anyone may do with this information. The &%$^#@ environmentalists have made the process of refrigeration into a big Three Ring Circus. The regulations that they have brought about are so stringent that one should never underestimate the ease of being a criminal when involved with any refrigeration process. Yes, There are high pressures involved, and I know that propane (R 290) is flammable and explosive and that there are many reasons that a system of this nature may not always be suitable for domestic uses. So Please spare me from letters and comments about my stupidity. This is not a plan for a practical, safe, reliable refrigerator. It's sole purpose was to observe a working refrigeration process using materials obtained from the nearest hardware store. The materials used are crude by refrigeration standards and the possibility of leaks are high, making this a project to strongly consider being done out of doors.

Some of the differences encountered when doing this are:

1. Propane operates at a higher pressure and the pump must be able to produce it. Most pumps will do that. The high side pressure will typically be 100 psig higher than with R-12

2. The temperatures from the evaporating coil may be different enough to disrupt proper operating of the thermostat since most systems sense the temperature of the evaporator coil. This can be taken care of by making a duty cycle timer or an inside air temp sensor. At the time of this writing, this has not been worked out. So far, the refrigerator has been operated by manually turning it on and off. It seems to have no trouble running for many hours at a time.

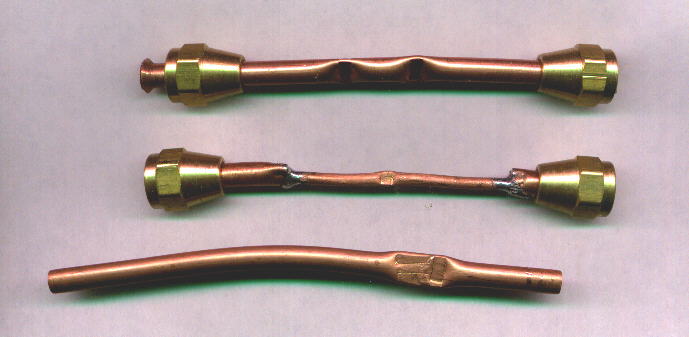

3. The capillary tube (expansion valve in previous project) may not have the optimum resistance. All cases tried so far have worked quite well. If not, a simple, and so far very satisfactory, expansion valve can be made by pinching a piece of copper tube. This must be done while watching meters to get it just right. Approx 15 psig seems to work well. The freezing of ice mentioned above was done using a pinched tube. The pinched tube has been operating very consistantly on an ocasionally used system.

4. And of course, propane is flammable. There are vary widely varying opinions about this. Many believe the risk is minimal and are trying to promote the use of hydrocarbon refrigerants. Propane for example, is an excellent refrigerant.

Note the buildup of frost on the return tube all the way to the pump.

This replaced the capillary tube which was removed. This was done mostly to see if it would work. The original capillary tube seemed to also work ok. This is where the high pressure liquid refrigerant shoots into the low pressure side and evaporates to become very cold. Notice how the low pressure side is completely covered with frost.