I have found that a vacuum tube can operate at a vacuum level easily attainable by amateurs. We certainly are not talking about optimum performance, but rather an experiment to satisfy a life long curiosity about how high of vacuum is required to make a vacuum tube operate.

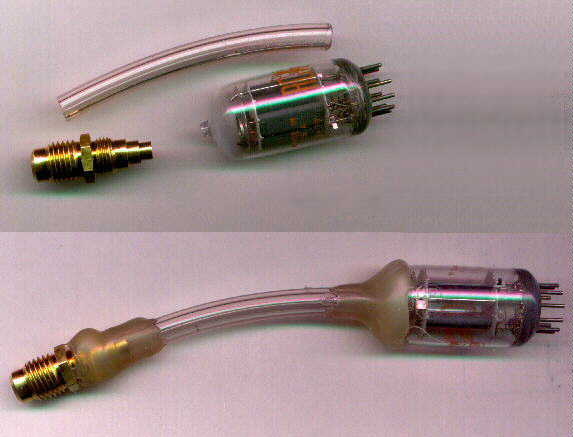

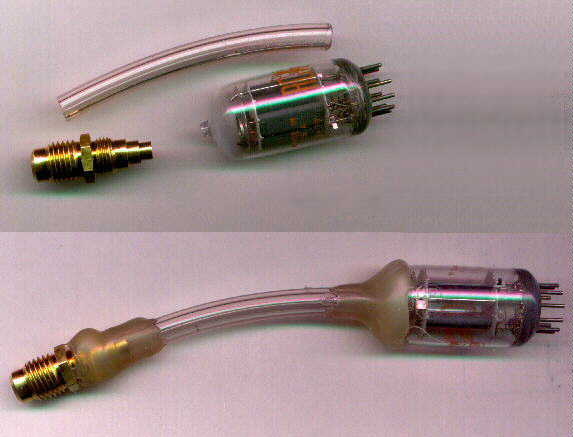

I had a couple of 5965 (equivalent to 12AV7) dual triode tubes and opened one to the atmosphere, let air inside and then attached a hose for connection to a vacuum pump. As the picture below shows, it was a simple operation. Notice how the normally mirror like getter (at the top of the tube) is now powdery white from being attacked by the air. It took roughly 30 minutes for the bright silvery film to turn white after breaking the seal on top of the tube.

The pump that I used is an old Robinair refrigeration service pump. I don't know how well hot glue is suited for high vacuum connections, but The pump is capable of getting down to 10 microns or below according to a Supco thermister vacuum gauge. A small degree of vacuum tube operation was observable at pressures as high as 1 torr but as expected, the tube worked much better at lower pressures of about 50 microns and below. Most of the experimenting described here was done at around 50 microns and below. When the vacuum was close to 10 microns, I would turn on the filament and notice an immediate climb in pressure from the hot filament outgassing. After several times of heating, however the vacuum would stay down.

The first attempt of observing vacuum tube operation was to connect the cathode and plate to an old Tecktronix 575 curve tracer. The grid was connected so that I could connect it to either the cathode, the plate or a biasing pot connected to a 9 volt battery. This tube is a double triode with a center tapped filament. This allowed operation of just one triode with 6 volts applied to one of the filaments. With the normal 6 volts across the filament, no glow was seen because of the air inside keeping it cool. As the pump was turned on, the filament started to glow, but maybe not quite so brightly as normal. Changes in current drain from the filament were very noticeable as the degree of vacuum changed and thus changed the temperature and resistance of the filament. This was observed simply by having a volt meter across the filament and watching the voltage change from a varying load. With a given voltage applied to the filament one might be able to build a good vacuum gauge by using a vacuum tube connected to a bridge circuit and a meter.

In order to observe any vacuum tube action at all, It was necessary to run the filament voltage much higher than normal - about 10 to 12 volts. According to the indications on the curve tracer, the tube seemed to be operating to a reasonable degree. One certainly would not expect full spec operation under these types of conditions. With 100 volt sweep on the plate and a 20k resistor, I was easily able to get a plate voltage change of about 40 volts from a 3.5 volt bias change on the grid. That seems to indicate a very usable amount of amplification.

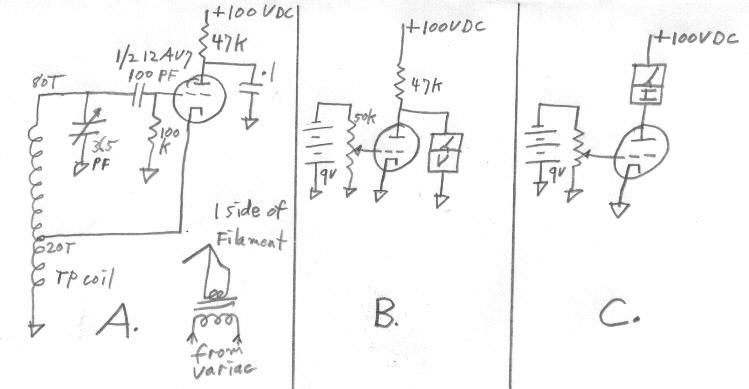

The next step was to put my home evacuated tube to the real test by connecting it into an actual circuit such as an amplifier or oscillator. I did just that and had no difficulty in making a Hartley type broadcast band oscillator run with 9 volts applied to the filament. See schematic A. As the oscillator ran, I would turn off the vacuum pump and watch the oscillator signal on an oscilloscope as the pressure rose. Unbelievably, I could keep the oscillator running as the pressure rose to as high as one torr (1000 microns). The filament voltage had to be raised to 11 volts in order to keep it going at this pressure. The oscillator signal was much weaker at one torr, but it is fascinating that it could run at such high pressure in the tube.

I also connected it into an amplifier configuration and varied the grid input voltage swing while watching the plate voltage swing. See schematic B. I measured a voltage gain of about 15 or 16, a definitely usable gain.

Transconductance measurements were made using schematic C. The tube plate output current curve reflects positive as well as negative grid voltage. I only made transconductance measurements between zero and minus grid voltage. In this range the tube generally drew about 1 ma plate current using 100 volt plate supply. That didn't seem bad for a homepumped vacuum tube. Varying the grid voltage between minus 1.265 volts and minus .679 volts (.586 volt change) caused the plate current to vary from .5 ma to 1.5 ma. This calculated to be a transconductance of about 1700 micromhos.

It may also be possible to make a vacuum gauge by measuring the plate conductance to the tube. Perhaps a versatile gauge could be made for two different ranges of vacuum by using the filament heat transfer method for one range and the plate conductance change method for another range.

The use of vacuum tubes, under the conditions described above, is a very adverse condition for the filaments. Four filaments became history in the course of the above experimentation.

I hope soon, to try making a homemade vacuum tube completely from scratch. Even if it's operation is crude and has to have the pump running during its operation, it will be a very satisfying experience. It is something I have thought about all my life. The experiments described above make prospects for a crude homemade vacuum tube quite encouraging.